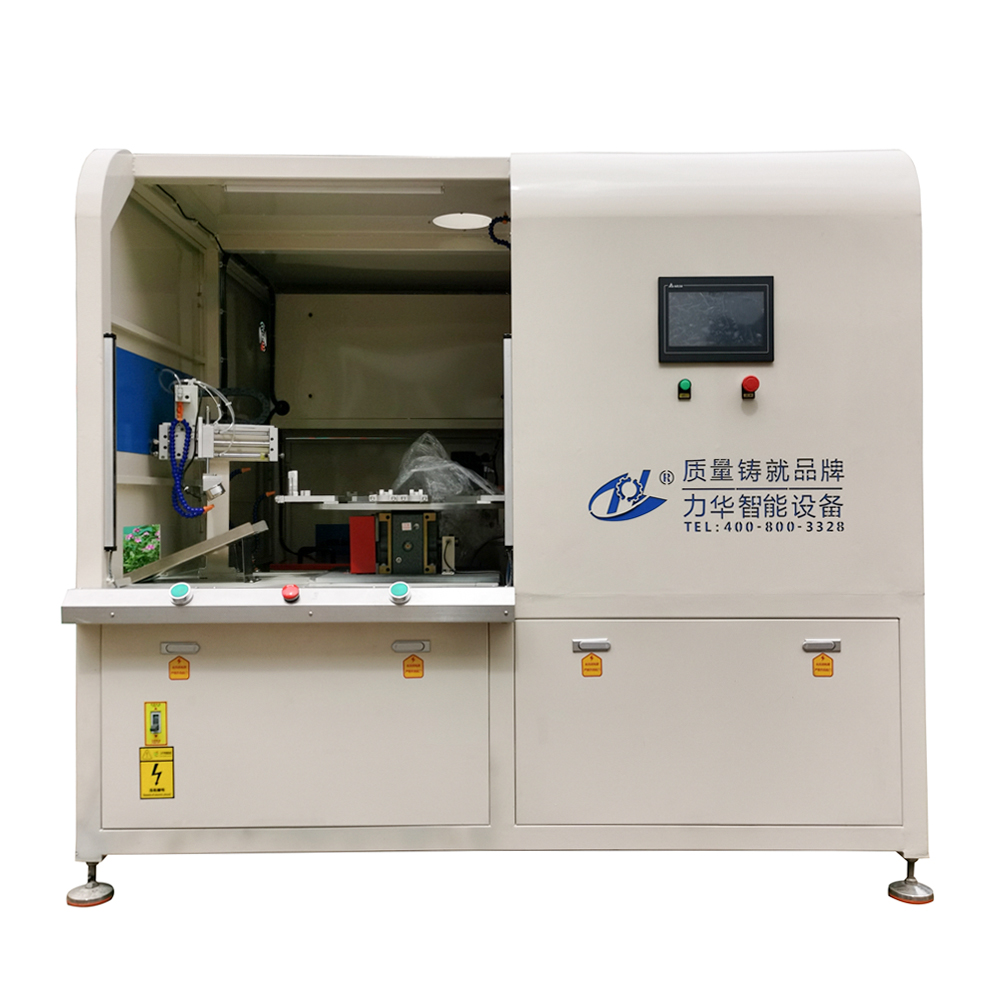

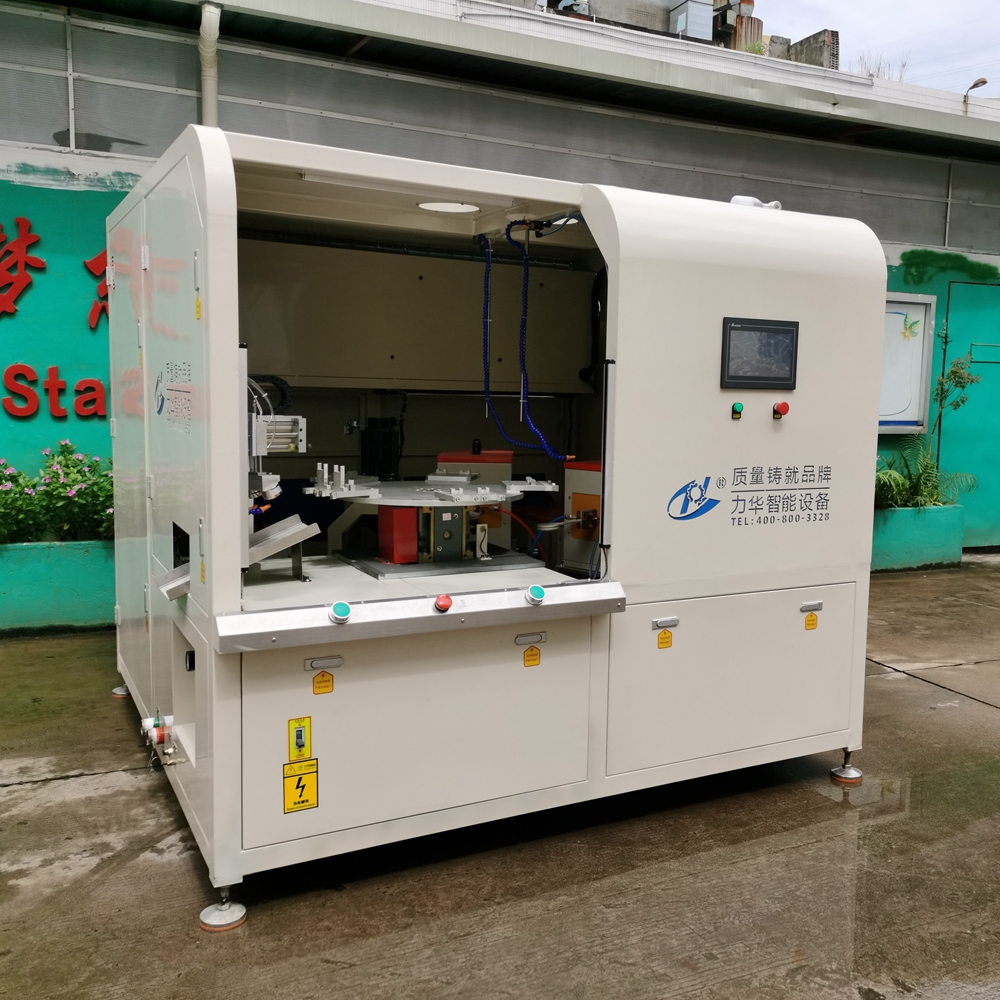

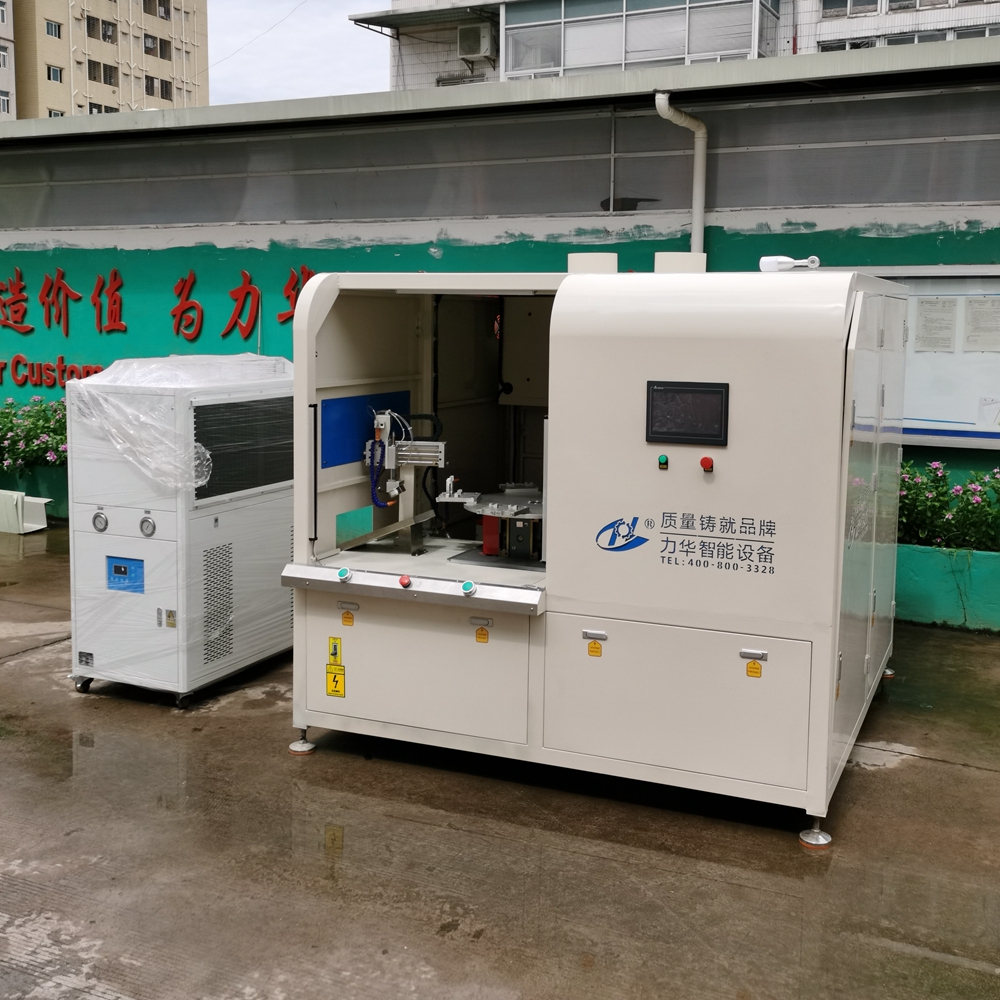

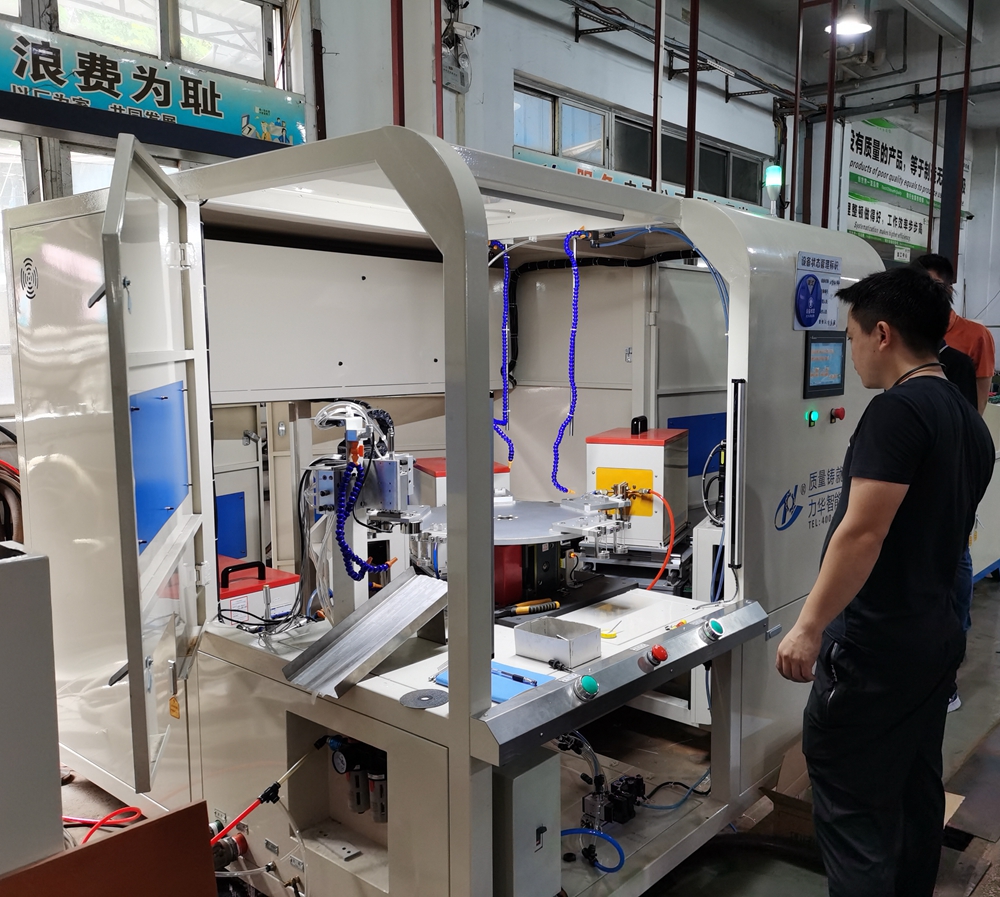

Rotary oil tube brazing machine

- SERVICEOEM/ODM

- MOQ1 SET

- DELIVERY TIME20-30 DAYS

- ABILITY50 SETS/M

- CERTIFICATESCE/ISO

- PAYMENTT/T,L/C

-

Description

Rotary oil tube induction brazing machine is customized, characterized by simple operation and precise welding. All LIHUA’s induction brazing equipment is based on induction heating principle, that is under high temperature or high-pressure condition, welding two or more kinds of materials into a whole with solder (solder rod or solder wire).

Welding range of LIHUA’s induction brazing equipment:

Appliance industry:

■ Brazing of heating plates of electric kettle, soy milk barrel, vacuum kettle, heat preservation pot, teapot, coffee pot, etc.

■ Brazing of multiple bottoms of various pots, frying pans, steamers, and rice cookers.

■ Brazing of stainless steel radiators.

Refrigeration industry:

■ Brazing of four-way valve parts and copper pipes of household air conditioners.

Aerospace industry:

■ Brazing of instrument panel.

Hardware accessories industry:

■ Brazing of carbide knife and knife handle.

■ Brazing of air conditioning condenser and copper joints.

■ Brazing of plumbing parts.

It is also widely used in industries requiring heat source equipment, such as automobiles, communications, medical equipment, and weapons industries.

-

FAQ

- Why choose LIHUA induction brazing equipment?

1. High safety factor: no need flammable and explosive gas, and guarantee the safety of life and property;

2. Saving energy and environmental protection: there isn’t carbon monoxide and carbon dioxide and other harmful gas during welding. The power source is electric, compared with acetylene, gasoline, oxygen, LPG and another source, the cost is much lower;

3. High welding quality: Flat welding surface, stable welding quality, improved the whole quality of the welding product;

4. It is easy to operate, ordinary workers can learn to operate within several seconds. - Why use induction heating?

★ Improved process efficiency

★ Localized, constant and precise heating

★ Temperature control

★ Energy saving

★ Possibility of integration into production lines

★ Best quality and yield/performance

★ Pollution free, fast and secure technology

★ Improved working environment. - Are you a factory or trading company?

We are a professional manufacturer of induction heating equipment since 2005. Welcome to visit our factory anytime.

- Do you have any equipment in stock?

Yes, we have some standard models in stock, and can deliver immediately after payment.

- How is your quality control?

We have a professional team responsible for product testing and packaging before delivery. You can buy without hesitation.

- If the machine get damaged, what can I do?

Some spare parts are free of charge during the one-year warranty period. If you don't know how to repair, please take photos or record a video and send to us, our engineer will guide you to perform the repair. If still cannot solve the problem, we can send our engineers to your factory.

- Why choose LIHUA induction brazing equipment?