首页公司简介

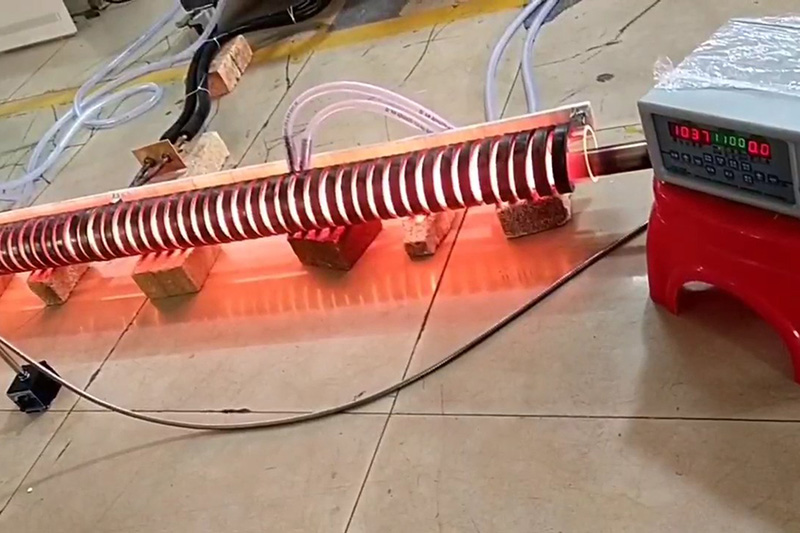

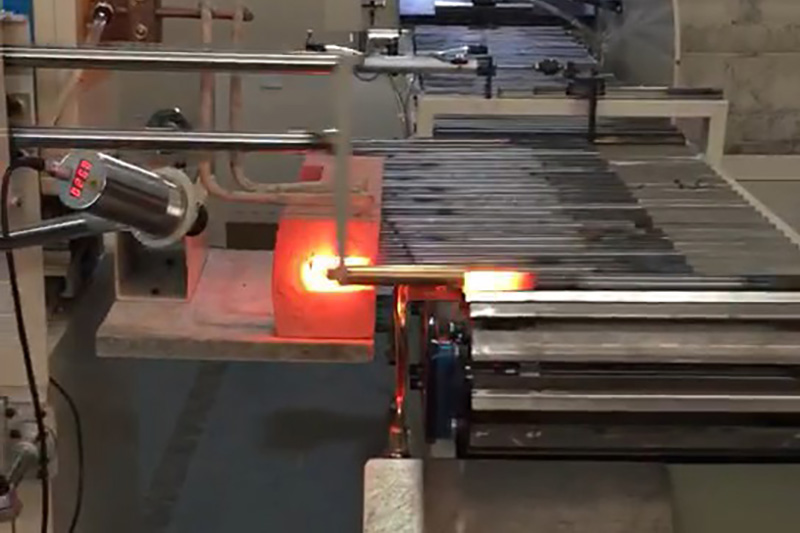

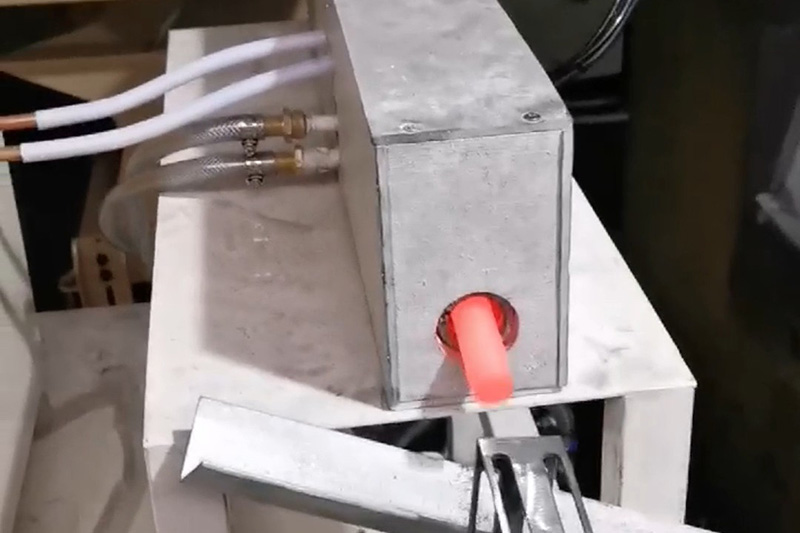

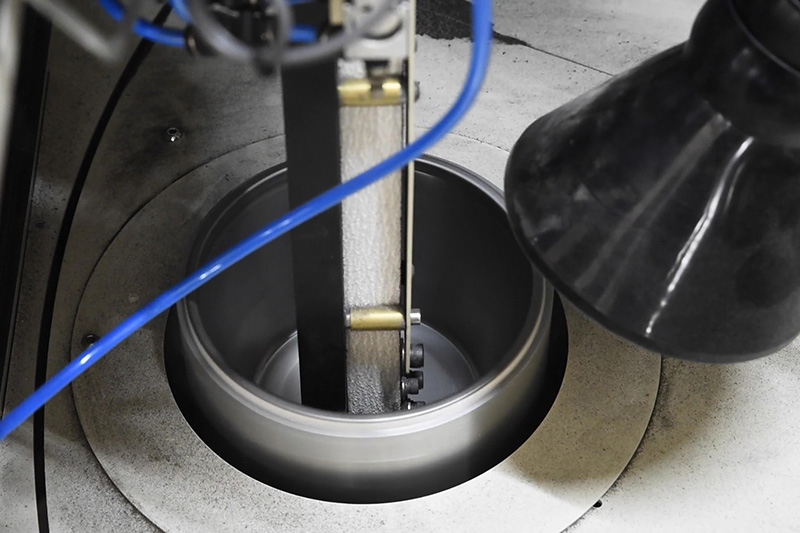

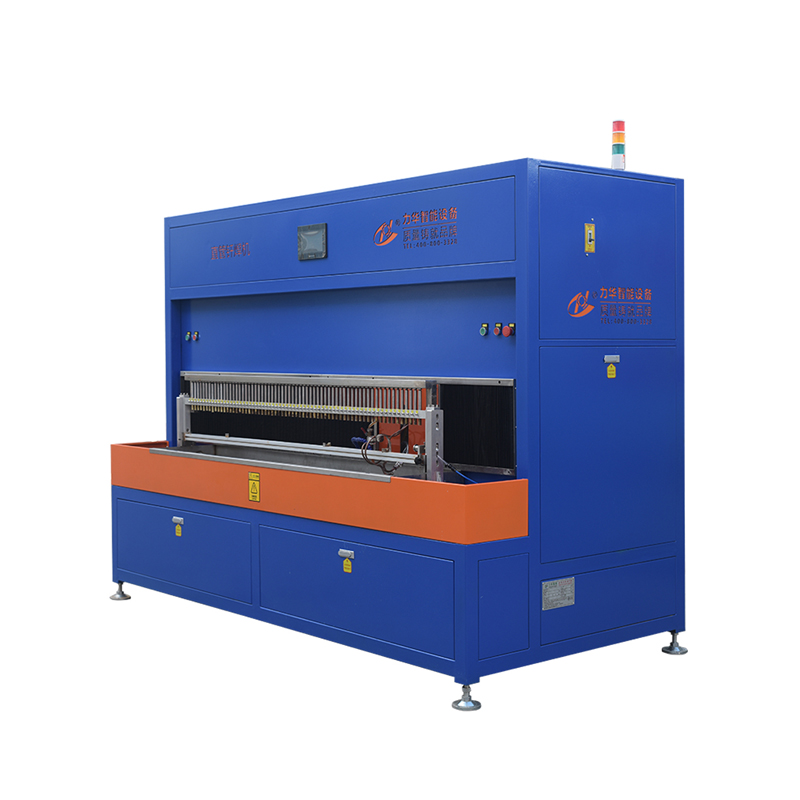

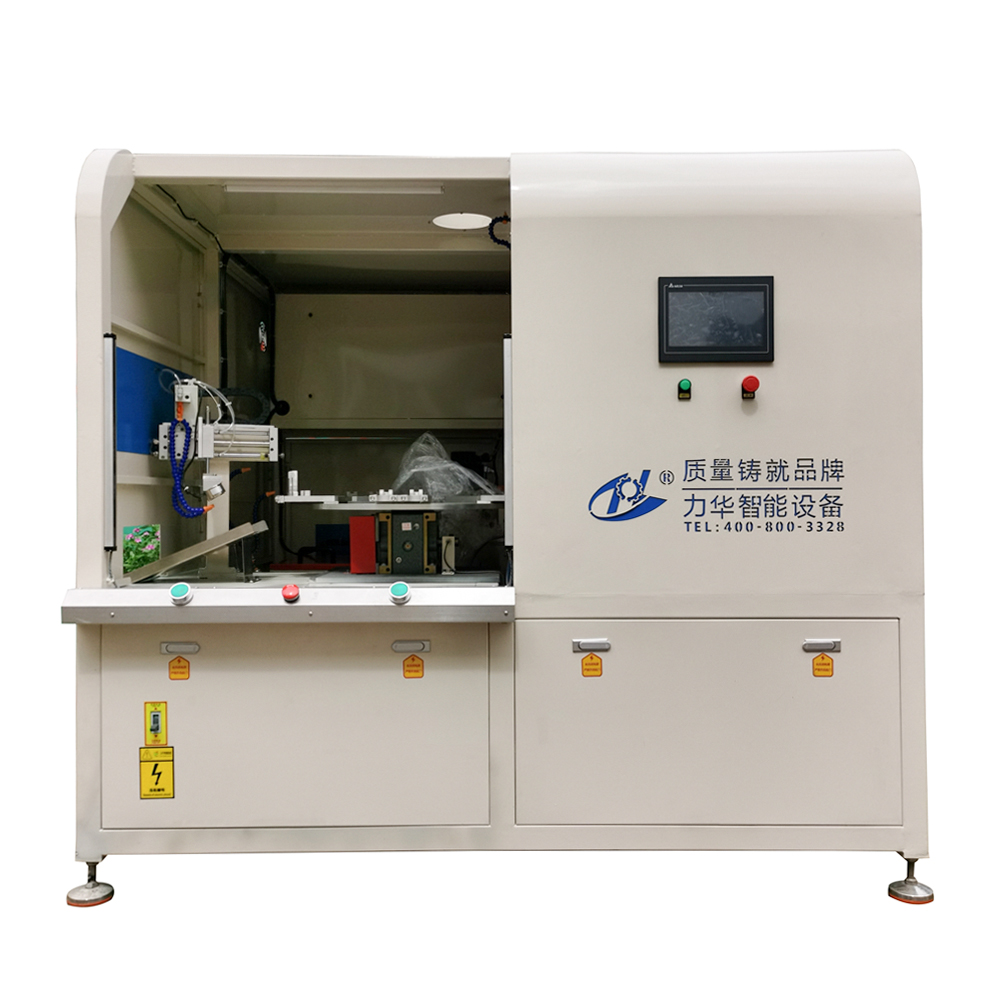

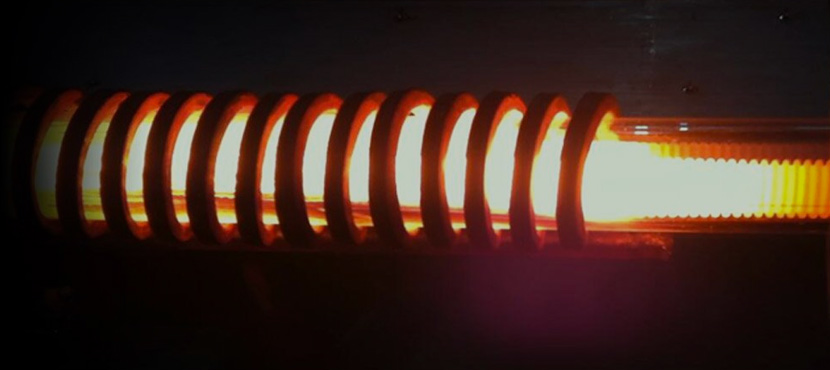

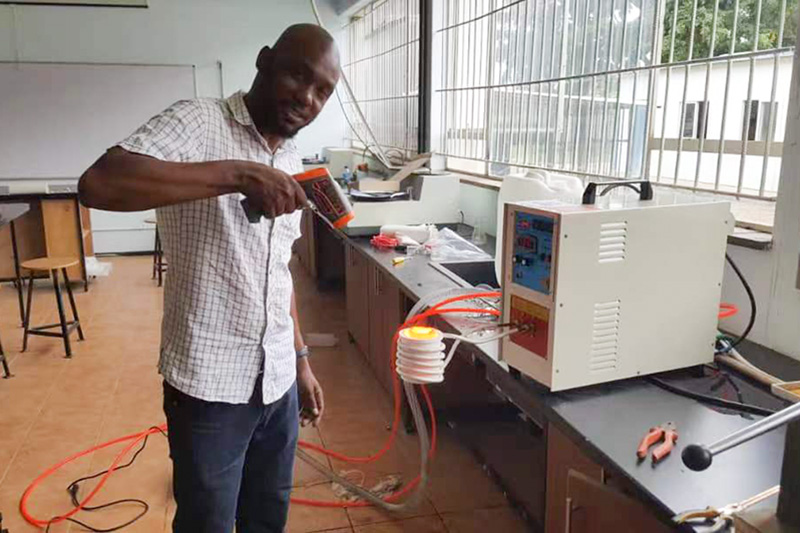

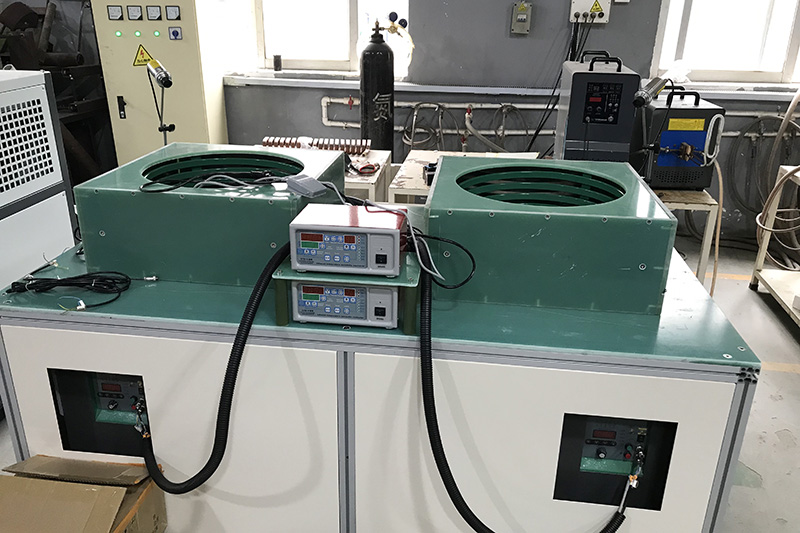

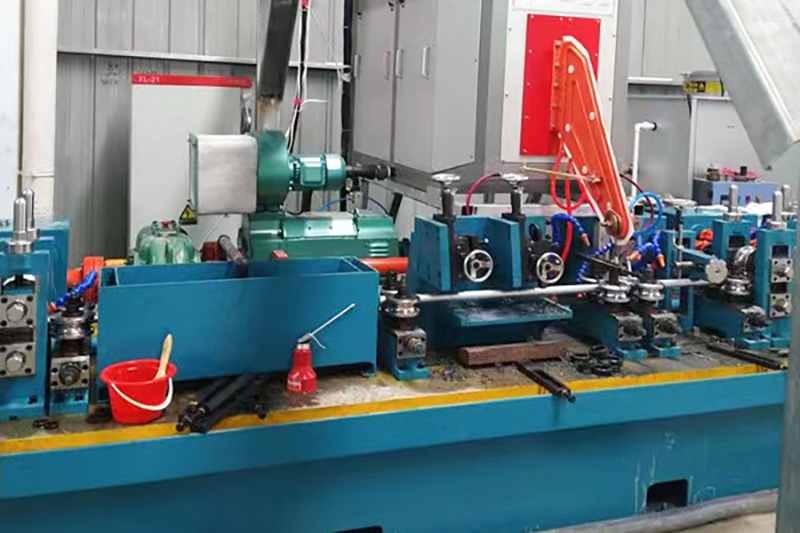

Lihua Technology (HK) Industrial Co., Ltd. is the foreign trade branch of Guangdong Lihua Induction Equipment Co., Ltd. We are a professional induction heating equipment manufacturer in China. Our modern garden-style factory covers an area of 10,000 square meters. We produce induction heating machine, induction brazing machine, induction hardening machine, induction annealing machine, induction melting furnace, induction forging furnace etc. All these induction heating equipment are widely used in the metal heat treating industry.

All our machines have passed CE certification. These machines have undergone full inspection and commissioning to make sure the quality. These machines adopts IGBT or MOSFET module, having over current protection, over voltage protection, water shortage protection, overheat protection, short circuit protection and phase lack protection.

We have strong R&D team, professional sales team, high-efficiency production team, and 24-hour online after-sales team, thus attracts customers from all over the world. We export to over 40 countries and districts, such as USA, UK, Turkey, India, Pakistan, Egypt, Thailand, Russia, Argentina, France, Spain and South Africa.

Since 2005, we have completed 8 times production process optimizations and 5 times production equipment updates. We obtained the honor of national high-tech enterprise and more than 60 patent certificates. Drawing out in 1 day, sample out in 3 days, OEM and ODM are our specialties.

We are a reliable supplier of induction heating equipment with 1-year warranty and lifetime technical support. We are looking forward to a win-win cooperation with you!