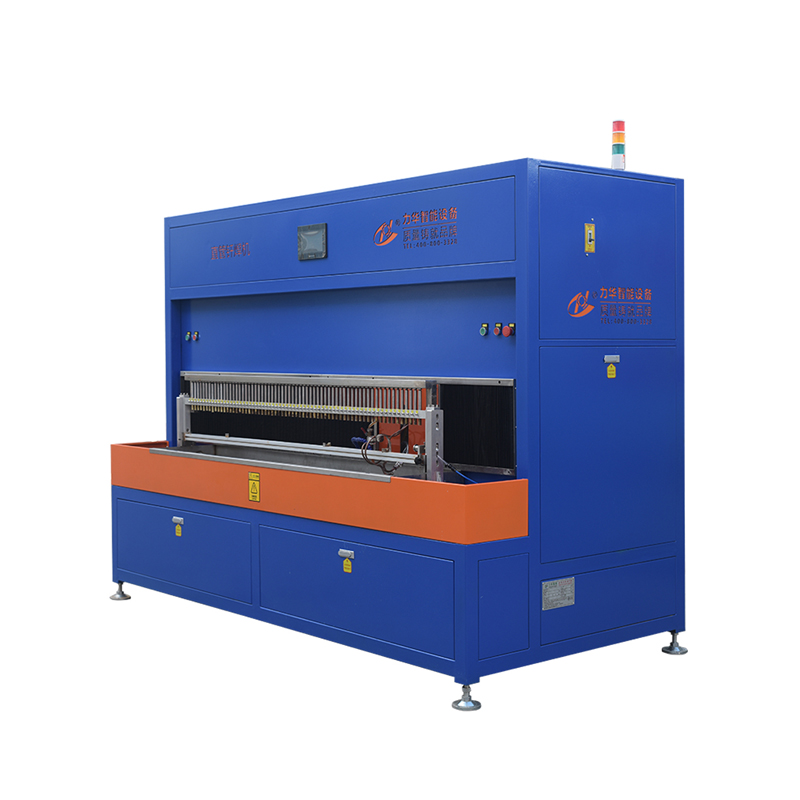

Three-station bottom brazing machine

- SERVICEOEM/ODM

- MOQ1 SET

- DELIVERY TIME20-30 DAYS

- ABILITY50 SETS/M

- CERTIFICATESCE/ISO

- PAYMENTT/T,L/C

-

Description

LIHUA has been developing induction brazing equipment since 2005, and enjoys a high reputation in the small household appliance industry. We have unique welding technology and self-developed induction heating power supply. LIHUA new generation three-station bottom brazing machine combines the new compound bottom technology with high frequency induction heating principle, to braze stainless steel pot, copper pot, aluminum pot or other containers.

Application:

■ It is suitable for multi-layer brazing of round, square, ellipse and special-shaped pot bottoms.

■ Brazing diameter range φ100- φ600.

Characteristics:

1. Production capacity: 5- 10 pcs/min (varies from different sizes) ;

2. The compound pot bottom is heated to the proper temperature in three times, which effectively avoids the heating blind zone of the plane inductor, so as to make the heating more uniform;

3. Adopts pure water circulation system, digital monitoring system, PLC automatic control system, CPU automatic detection of water flow, fault diagnosis function;

4. The rotary table is easy to operate and greatly improves the work efficiency.

-

Parameters

Model LH-FDJ-30 LH-FDJ-60 LH-FDJ-80 LH-FDJ-100 LH-FDJ-120 LH-FDJ-150 LH-FDJ-200 Output power 30 kW 60 kW 80 kW 100 kW 120 kW 150 kW 200 kW Frequency 200- 300 kHz 200- 300 kHz 200- 300 kHz 200- 300 kHz 200- 300 kHz 200- 300 kHz 200- 300 kHz Max oil pressure 100 MPa 100 MPa 100 MPa 100 MPa 100 MPa 100 MPa 100 MPa Working pressure 2- 3 MPa 2- 3 MPa 2- 3 MPa 2- 3 MPa 2- 3 MPa 2- 3 MPa 2- 3 MPa Product size Diameter 100- 600 mm, Aluminum plate thickness 0.2- 12 mm, Height 100- 600 mm -

FAQ

- Why choose LIHUA induction brazing equipment?

1. High safety factor: no need flammable and explosive gas, and guarantee the safety of life and property;

2. Saving energy and environmental protection: there isn’t carbon monoxide and carbon dioxide and other harmful gas during welding. The power source is electric, compared with acetylene, gasoline, oxygen, LPG and another source, the cost is much lower;

3. High welding quality: Flat welding surface, stable welding quality, improved the whole quality of the welding product;

4. It is easy to operate, ordinary workers can learn to operate within several seconds. - Why use induction heating?

★ Improved process efficiency

★ Localized, constant and precise heating

★ Temperature control

★ Energy saving

★ Possibility of integration into production lines

★ Best quality and yield/performance

★ Pollution free, fast and secure technology

★ Improved working environment. - Are you a factory or trading company?

We are a professional manufacturer of induction heating equipment since 2005. Welcome to visit our factory anytime.

- Do you have any equipment in stock?

Yes, we have some standard models in stock, and can deliver immediately after payment.

- How is your quality control?

We have a professional team responsible for product testing and packaging before delivery. You can buy without hesitation.

- If the machine get damaged, what can I do?

Some spare parts are free of charge during the one-year warranty period. If you don't know how to repair, please take photos or record a video and send to us, our engineer will guide you to perform the repair. If still cannot solve the problem, we can send our engineers to your factory.

- Why choose LIHUA induction brazing equipment?