Automatic gear hardening machine

- SERVICEOEM/ODM

- MOQ1 SET

- DELIVERY TIME20-30 DAYS

- ABILITY50 SETS/M

- CERTIFICATESCE/ISO

- PAYMENTT/T,L/C

Description

Automatic gear induction hardening machine is customized for gear quenching, and has the characteristics of energy saving, environmental protection, intelligence, automation, less oxidation and less deformation. Equipment customization is Lihua's advantage! Lihua has been committed to induction heating for 21 years. We can quickly provide effective solutions for your special process requirements.

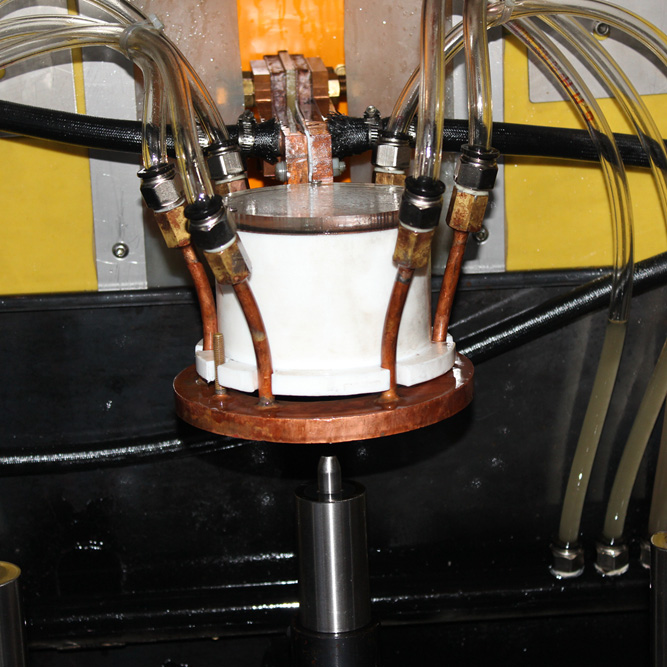

Induction quenching equipment is our heat treatment systems for surface and through hardening. At the heart of each quenching machine is an induction heating generator, which adopts the latest IGBT / MOSFET power units and unique frequency conversion technology. Induction hardening equipment consists of induction power supply, load line, capacitor, transformer, inductor, and machine tool. The quenching family includes horizontal type, vertical type and special machine, and compensated induction power sources with a wide range of output frequency and power.

Features of Induction quenching equipment:

■ The heat source is on the surface of the workpiece, fast heating speed, high thermal efficiency.

■ Because the workpiece is not been integrally heated, deformation is small.

■ The heating time is short, and the amount of decarburization is less.

■ The surface hardness of the workpiece is high, the notch sensitivity is small, and the impact toughness, fatigue strength and wear resistance are greatly improved. It is beneficial to realize the potential of the material, save material consumption, and improve the service life of parts.

■ The equipment structure is compact, easy to use and good in working conditions.

■ It is convenient for mechanization and automation.

■ It can be used not only in surface quenching but also in penetration heating and chemical heat treatment.

■ Induction quenching is not only applied to the surface hardening, but also to the internal hole hardening, which is not achieved by traditional heat treatment.

■ By means of induction heating quenching, ordinary carbon structural steel can be used instead of alloy structural steel and carburizing steel to make fittings without reducing the quality of parts. Therefore, under certain conditions, chemical heat treatment with a complex process can be replaced.

Parameters

Equipment power 10- 300 kW Quenching method Continuous quenching, simultaneous quenching, continuous quenching in sections, simultaneous quenching in sections Quenching dimension range Shaft: φ10- 300 mm, L:50- 3000 mm

Gear: φ20- 2000 mm, H:10- 500mmMaximum quenching weight 500 kg X axis travel 200 mm Y axis travel 300 mm Z axis travel 1500 mm FAQ

- Why choose LIHUA induction quenching equipment?

1. The heat source is on the surface of the workpiece, fast heating speed, high thermal efficiency, small deformation, less amount of decarburization.

2. The surface hardness of the workpiece is high, the notch sensitivity is small, and the impact toughness, fatigue strength and wear resistance are greatly improved.

3. It can be used not only in surface quenching but also in penetration heating and chemical heat treatment.

4. Lihua Gear and Shaft quenching machine has the function of continuous quenching, simultaneous quenching, continuous quenching in sections, simultaneous quenching in sections.

5. Variable frequency speed control system, servo motor drive, ball screw drive.

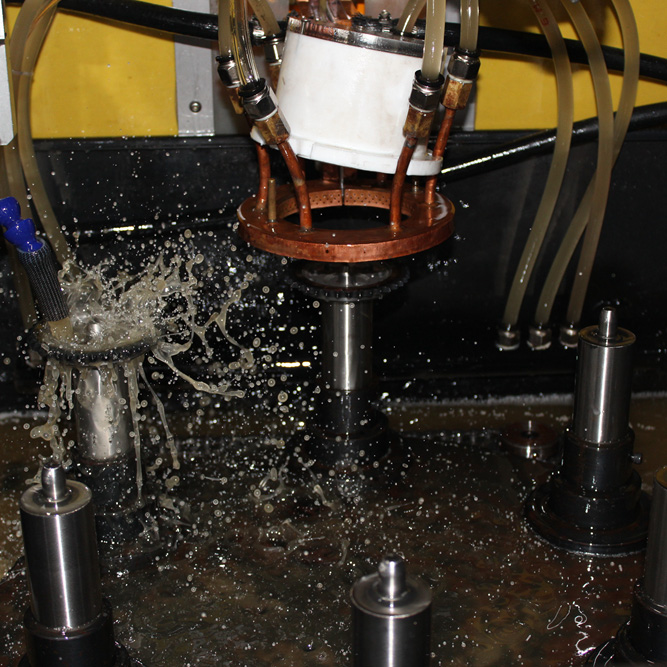

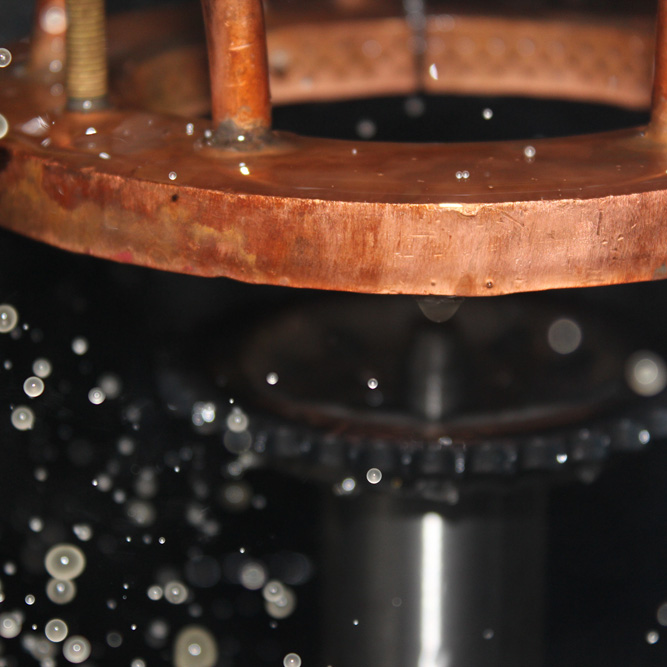

6. Both two cooling methods immersion and spraying are available for the equipment , it can be equipped with the integrated quenching liquid circulating cooling system.

7. Adopts CNC system and PLC touch screen to control the equipment, the equipment is without programming, convenient operation, real-time display, can store 126 programs, concentrate heating→ positioning→ spraying and time controlling on the control system of machine, easy positioning and scanning, and connect with induction generator through PLC , realize automatic production.

8. High resetting precision, small volume, light weight, easy maintenance.

9. According to the needs of the customer, a semi automatic or fully automatic high frequency quenching machine equipment can be customized. - Why use induction heating?

★ Improved process efficiency

★ Localized, constant and precise heating

★ Temperature control

★ Energy saving

★ Possibility of integration into production lines

★ Best quality and yield/performance

★ Pollution free, fast and secure technology

★ Improved working environment. - Are you a factory or trading company?

We are a professional manufacturer of induction heating equipment since 2005. Welcome to visit our factory anytime.

- Do you have any equipment in stock?

Yes, we have some standard models in stock, and can deliver immediately after payment.

- How is your quality control?

We have a professional team responsible for product testing and packaging before delivery. You can buy without hesitation.

- If the machine get damaged, what can I do?

Some spare parts are free of charge during the one-year warranty period. If you don't know how to repair, please take photos or record a video and send to us, our engineer will guide you to perform the repair. If still cannot solve the problem, we can send our engineers to your factory.

- Why choose LIHUA induction quenching equipment?