Search

Categories

More

Tags

Definition of induction brazing

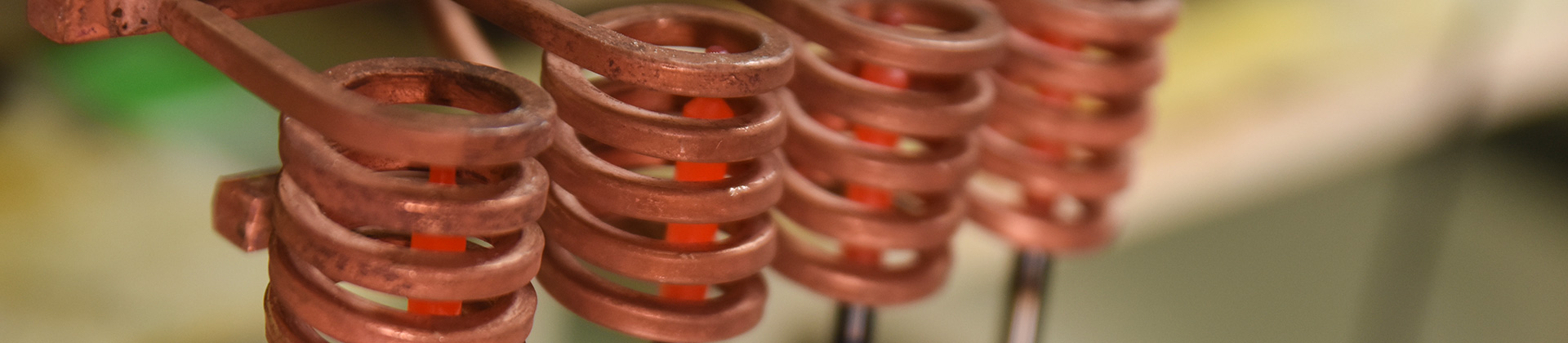

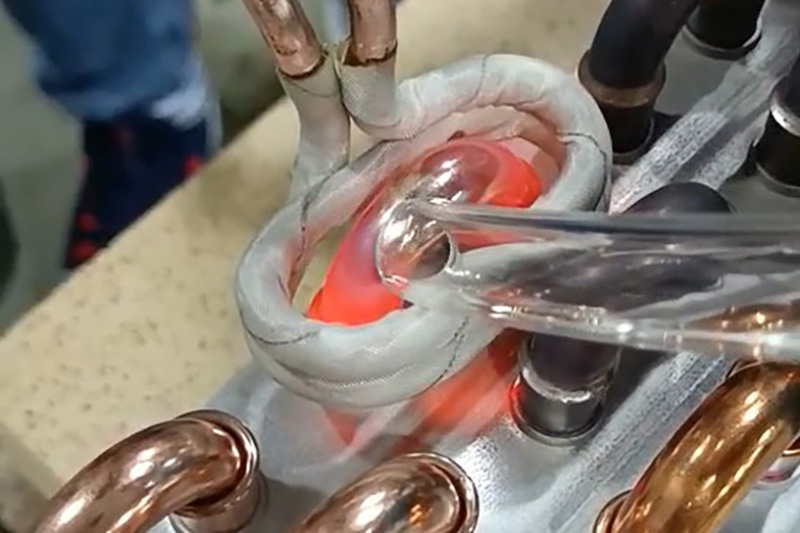

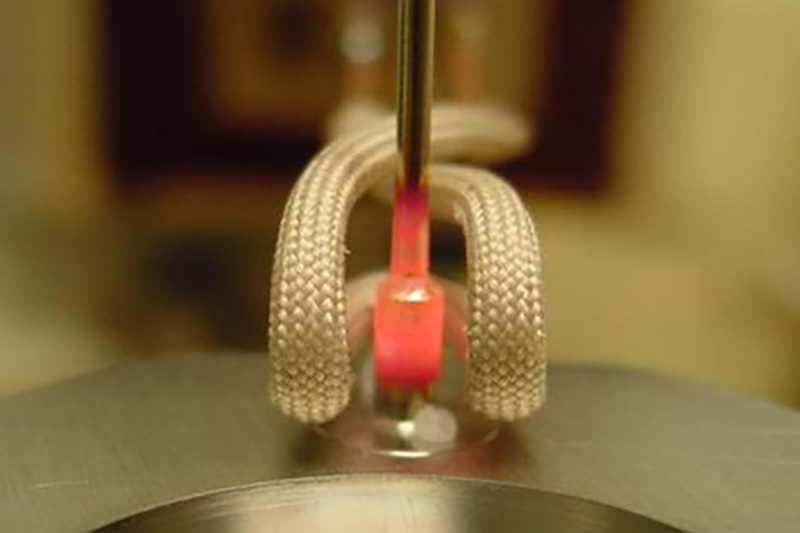

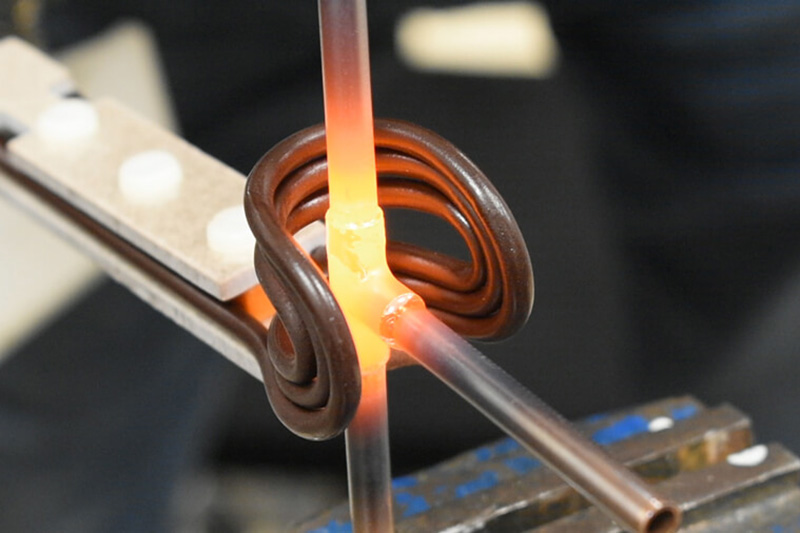

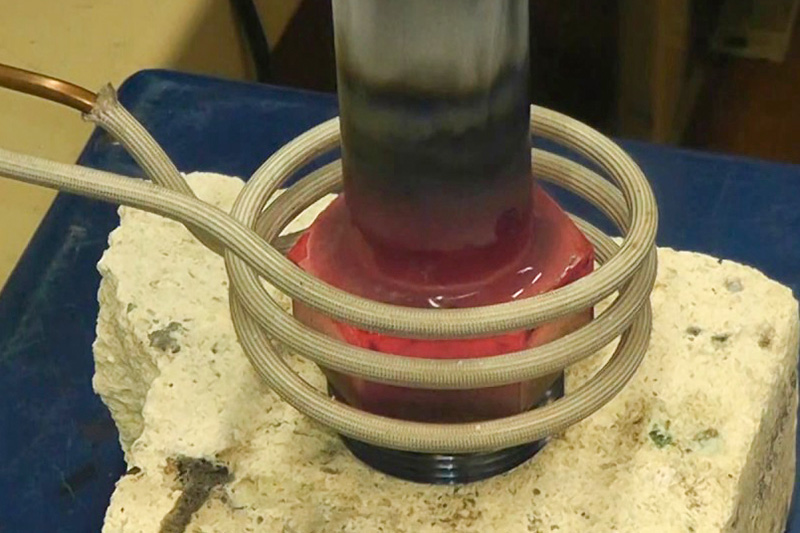

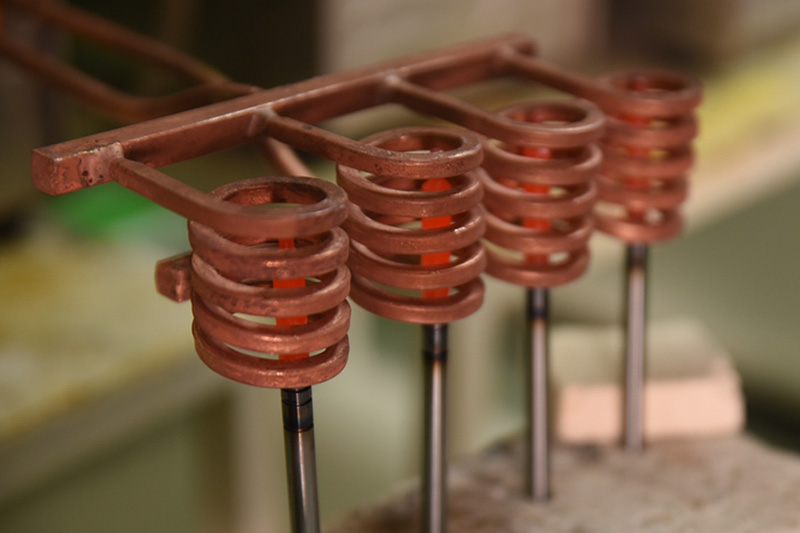

Induction brazing is a process in which two or more materials are joined together by a filler metal that has a lower melting point than the base materials using induction heating. In induction heating, usually metallic materials are heated rapidly from the electromagnetic field that is created by the alternating current from an induction coil.

Brazing filler metal selection

Brazing types | Suitable brazing filler metals |

copper to copper brazing | silver-copper solder, phosphor-copper solder, tin solder, brass solder |

copper to steel brazing | silver-copper solder, brass solder |

copper to aluminum brazing | aluminium alloy solder, tin solder |

steel to carbide brazing | silver-copper solder, brass solder |

steel to steel brazing | silver-copper solder, brass solder |

iron to iron brazing | silver-copper solder, brass solder |

iron to steel brazing | silver-copper solder, brass solder |

Copper joints brazing Video

Advantages of induction brazing

Induction brazing has high energy density and fast heating speed, which can greatly improve production efficiency. Can be targeted to provide heat to very small areas within tight production tolerances. Produces strong, clean, leak proof joints by preventing the filler from flowing in areas that it shouldn't flow. Green and safe, can work in vacuum or protective gas environment. For welding workpieces with specific insulation layers, the welding speed is fast and does not damage the insulation. Induction brazing enables automation and temperature control.

Applications of induction brazing

Induction brazing is widely used to braze weldments with symmetrical shapes made of steel, copper and copper alloys, stainless steel, high-temperature alloys. It is especially suitable for welding of pipe fittings, pipes to flanges, shafts to sleeves, turning tool bits and sawtooth pieces. In the small household appliance industry, induction brazing is often used for welding of electric kettle heating plates and multiple bottoms of various pots.