Search

Categories

More

Tags

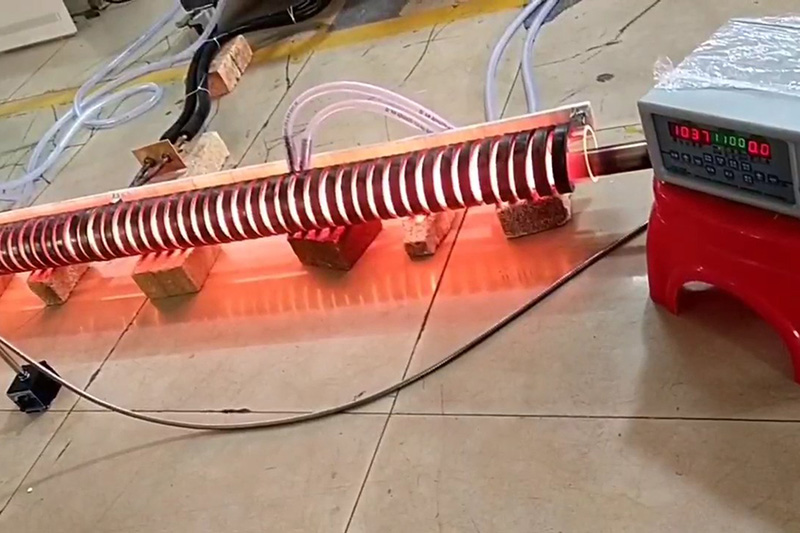

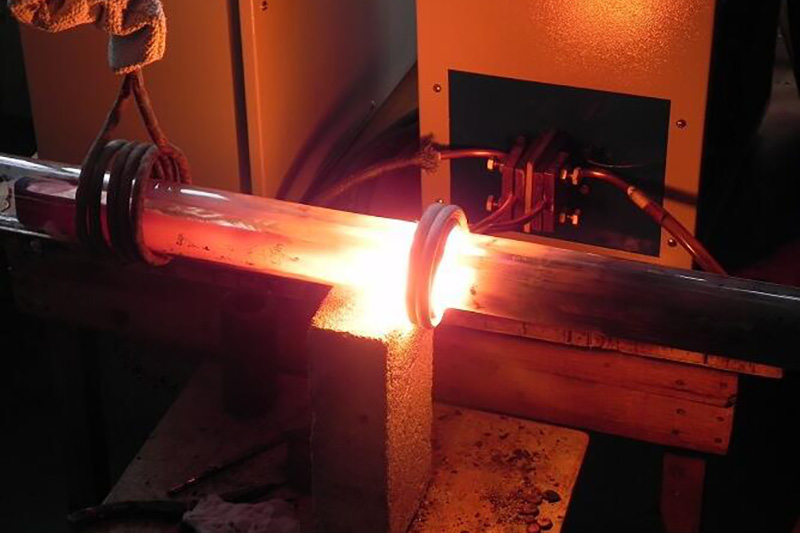

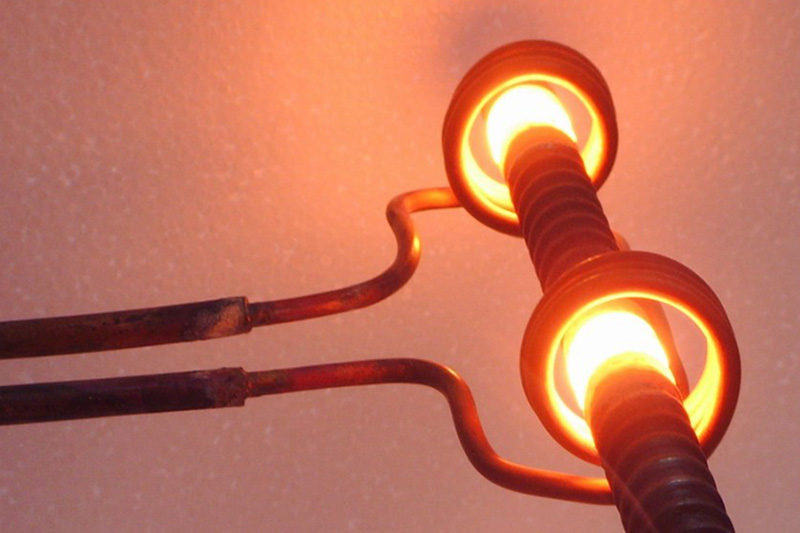

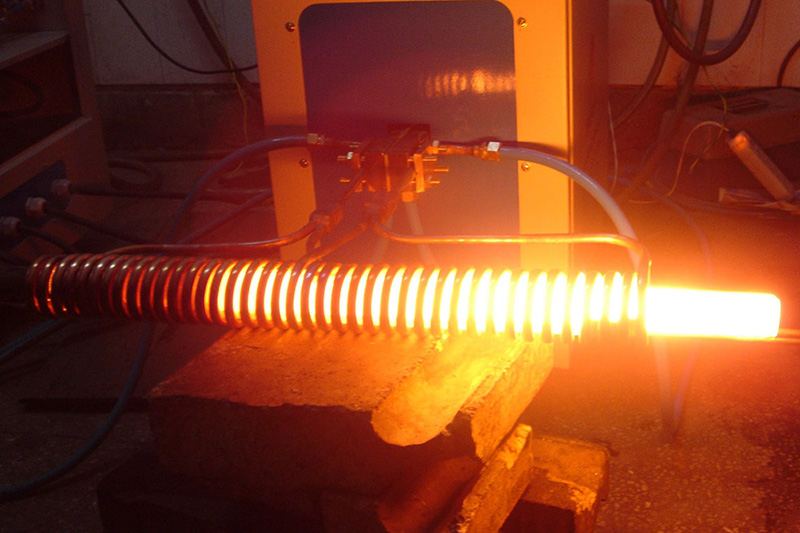

Definition of induction annealing

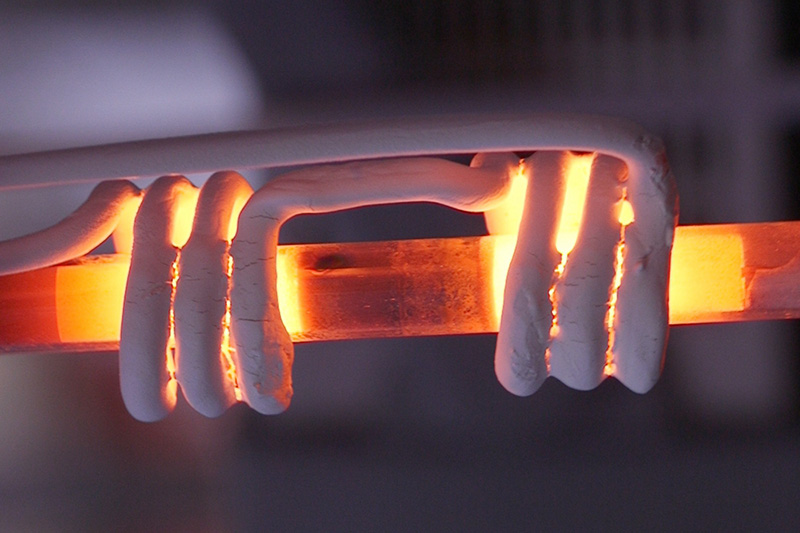

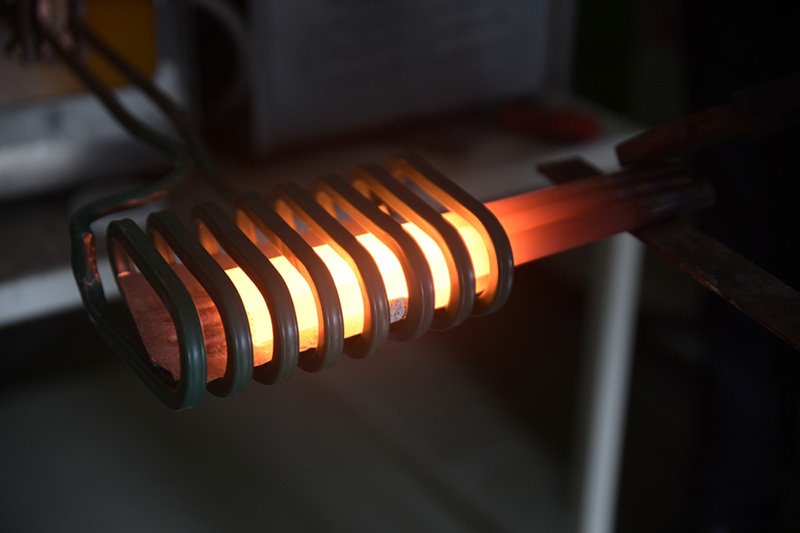

Induction annealing is a type of heat treatment process, in which a metal part is slowly induction-heated to a certain temperature, hold for a sufficient time, and then cooled at a suitable rate. The purpose is to reduce the hardness, improve the ductility and machinability; relieve internal stresses, reduce the tendency of deformation and cracks; refine the grains, adjust the structure, and eliminate the structure defects.

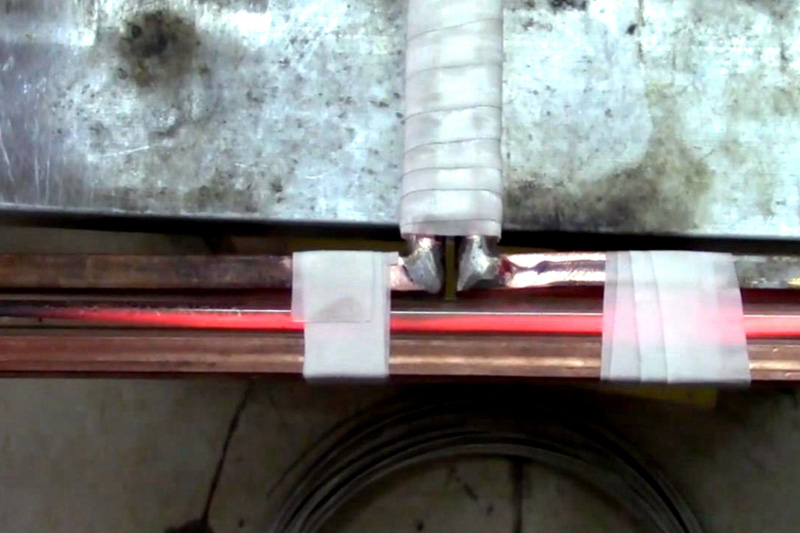

Spout annealing Video

Advantages of induction annealing

■ Online speed 0-90 m/min

■ Applicable to tubes φ3-φ40, sheets T0.5-T5.0, materials of iron, stainless steel, copper

■ Equipped with gas protection device, fast annealing, no deformation

■ Precise temperature control, and easy in-line integration

■ Can anneal multiple workpieces at the same time

■ Can run stably and continuously for one month

Applications of induction annealing

■ Annealing of the refrigerator condenser tubes

■ Annealing of Iron pipes, stainless steel pipes, copper pipes

■ Annealing of wire, tubing, strips

■ Annealing of stainless steel utensils after stretching

■ Various hardware tools annealing, such as knife blades, brass locks