Search

Categories

Related Info

Tags

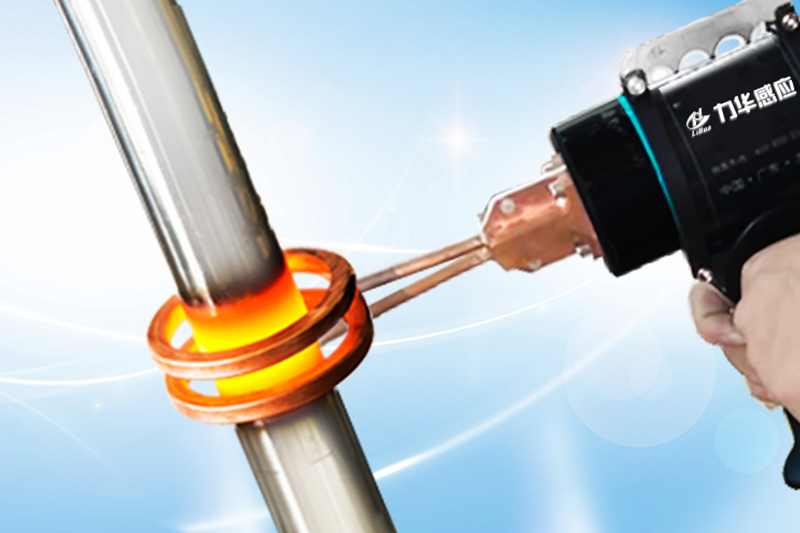

High-frequency mobile induction welding

Time:2023-08-18Mobile induction heating welding is a special welding method suitable for welding metal parts of different shapes and sizes. This method adopts the principle of induction heating, through the magnetic field generated by high-frequency alternating current, so that eddy currents are generated inside the metal parts, thereby generating heat and realizing welding.

Mobile induction heating welding equipment is composed of power supply, inductor, cooling system, control system and other parts. wherein, the power supply is used to generate high-frequency alternating current; Inductors are used to generate magnetic fields that generate eddy currents inside metal parts; The cooling system is used to cool the inductors and metal parts, maintaining the stability of the welding process; The control system is used to adjust the parameters of the power supply and inductors and control the welding process.

Mobile induction heating welding has the advantages of fast welding speed, high welding quality, small heat affected zone and convenient operation, and can be applied to the welding of various metal materials, such as copper, aluminum, stainless steel, etc. This method can also realize automatic welding, improve production efficiency, reduce labor intensity, and is suitable for large-scale production.