Tilting medium frequency induction melting furnace

- SERVICEOEM/ODM

- MOQ1 SET

- DELIVERY TIME20-30 DAYS

- ABILITY50 SETS/M

- CERTIFICATESCE/ISO

- PAYMENTT/T,L/C

-

Description

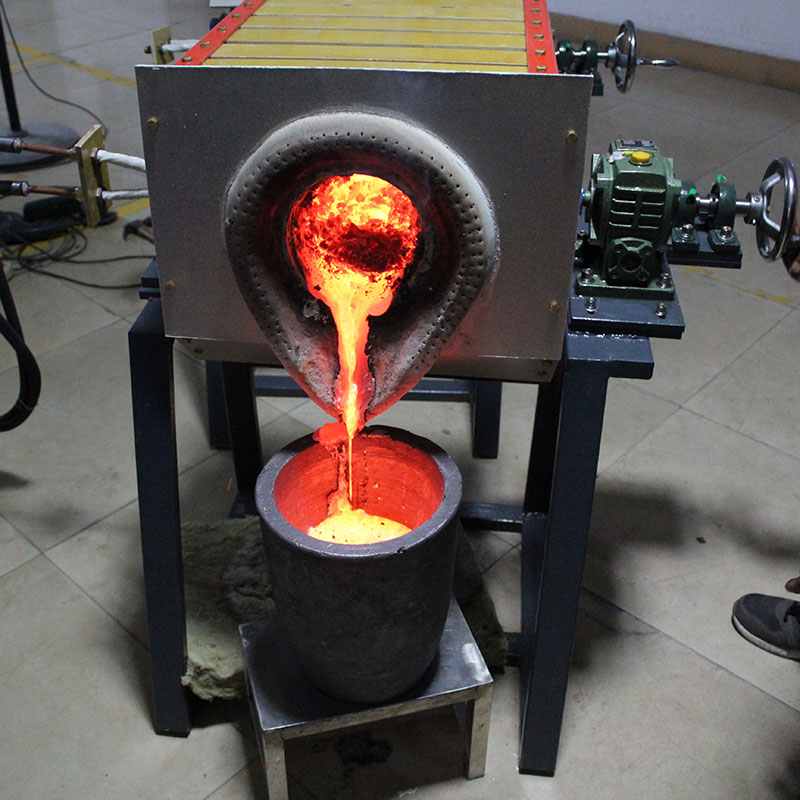

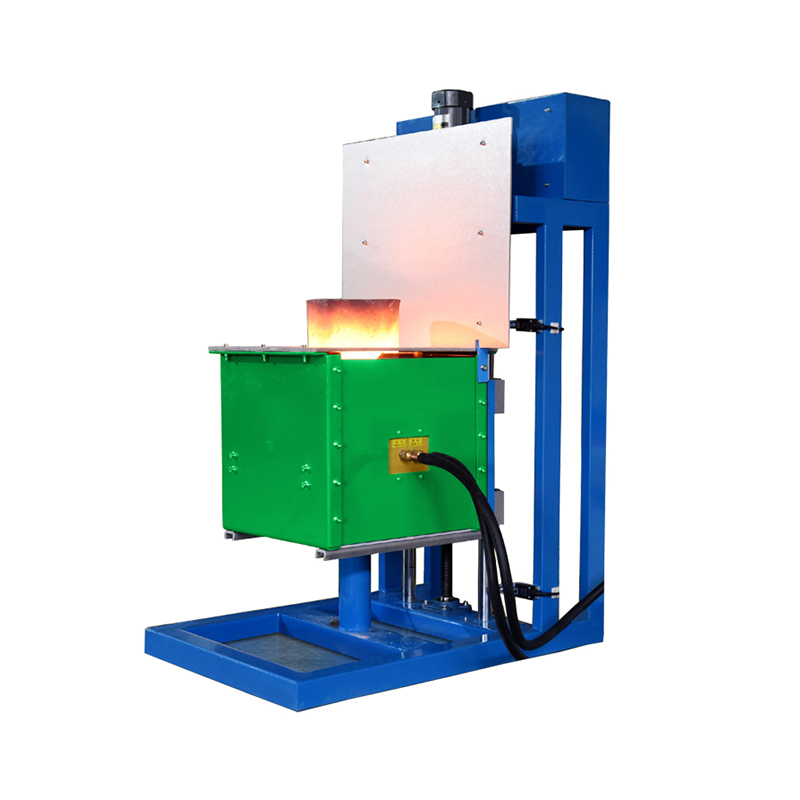

■ The tilting medium frequency induction melting furnace consists of medium frequency induction generator and furnace body.

■ The working principle is electromagnetic induction heating, which melts solid metal into liquid.

■ Melting metal materials such as steel, stainless steel, iron, copper, aluminum, aluminum alloy, gold, silver.

■ No flame, no emissions, environmentally-friendly.

■ Small in size, light in weight.

■ Smelting volume 3- 300 kg. (small capacity 1- 10 kg can use high frequency induction heating system)

■ Crucible selection: pure graphite crucible / clay graphite crucible / SIC crucible / magnesia crucible, choose according to metal material.

■ The dumping mode is divided into mechanical type and electric type.

■ According to different application requirements, it can be equipped with infrared thermometer, temperature controller and other devices.

-

Parameters

Model Steel / Iron Copper / Gold / Silver Aluminium LHRL-15KW 3 kg 10 kg 3 kg LHRL-25KW 5 kg 20 kg 6 kg LHRL-35KW 10 kg 30 kg 10 kg LHRL-45KW 18 kg 50 kg 20 kg LHRL-70KW 25 kg 100 kg 30 kg LHRL-90KW 40 kg 150 kg 50 kg LHRL-110KW 50 kg 200 kg 70 kg LHRL-160KW 100 kg 300 kg 100 kg -

FAQ

- Why choose LIHUA induction melting furnace?

1. Adopts full-solid IGBT frequency converter and power regulation, equips with all-round protection function, such as over current, water lack, over heat, over voltage, short circuit, lack phase and others, that greatly improves the reliability of equipment.

2. Equips with many display function, such as current display, voltage display, time display, to make the working situation more visualization. This function have guidance effect for design induction coil and capacity regulation.

3. 24-hours continuously melting.

4. Has electromagnetic stirring ability, to make melting more uniform.

5. Small volume, light weight, high efficiency, saving energy and saving electric.

6. Low temperature around the furnace, less smoke and dust and good working environment.

7. Easy operation process and stable running.

8. Uniform heating temperature, less consumption, uniform metal composition and good quality of casting.

9. It is fast to heat up to melting temperature, easy to control the furnace temperature, and widely used in various industries. - Why use induction heating?

★ Improved process efficiency

★ Localized, constant and precise heating

★ Temperature control

★ Energy saving

★ Possibility of integration into production lines

★ Best quality and yield/performance

★ Pollution free, fast and secure technology

★ Improved working environment. - Are you a factory or trading company?

We are a professional manufacturer of induction heating equipment since 2005. Welcome to visit our factory anytime.

- Do you have any equipment in stock?

Yes, we have some standard models in stock, and can deliver immediately after payment.

- How is your quality control?

We have a professional team responsible for product testing and packaging before delivery. You can buy without hesitation.

- If the machine get damaged, what can I do?

Some spare parts are free of charge during the one-year warranty period. If you don't know how to repair, please take photos or record a video and send to us, our engineer will guide you to perform the repair. If still cannot solve the problem, we can send our engineers to your factory.

- Why choose LIHUA induction melting furnace?