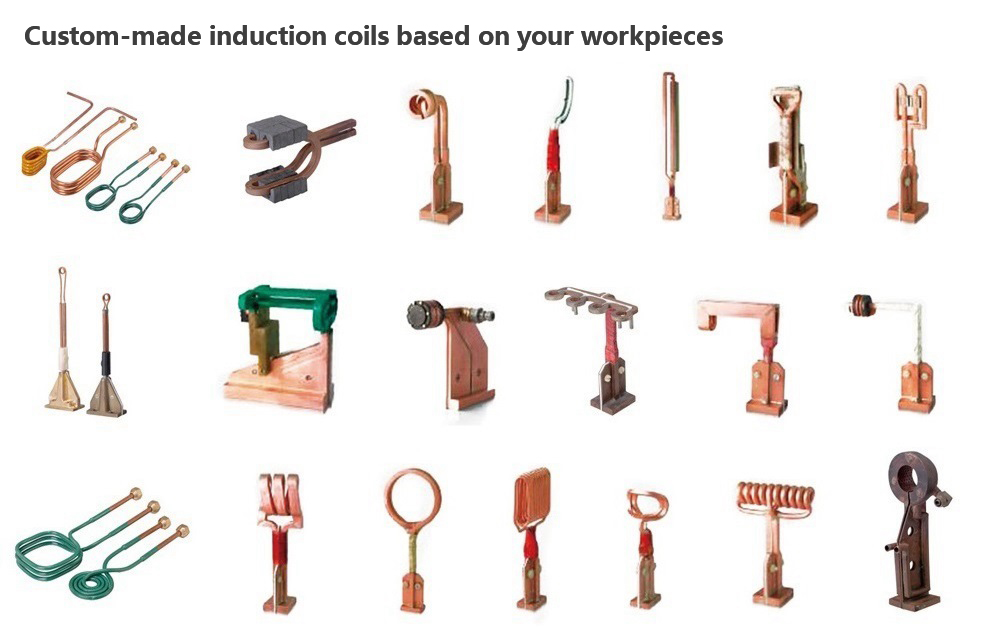

Induction heating coils

- SERVICEOEM/ODM

- MOQ1PCS

- DELIVERY TIME1-3 DAYS

- ABILITY3000PCS/M

- CERTIFICATESCE/ISO

- PAYMENTT/T,L/C

-

Description

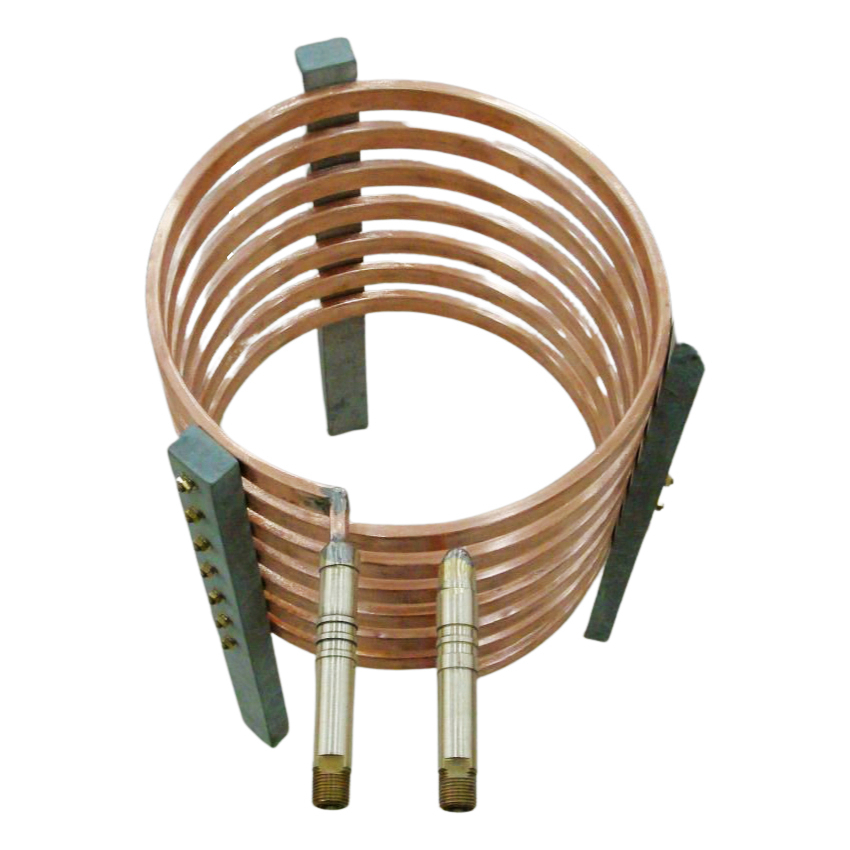

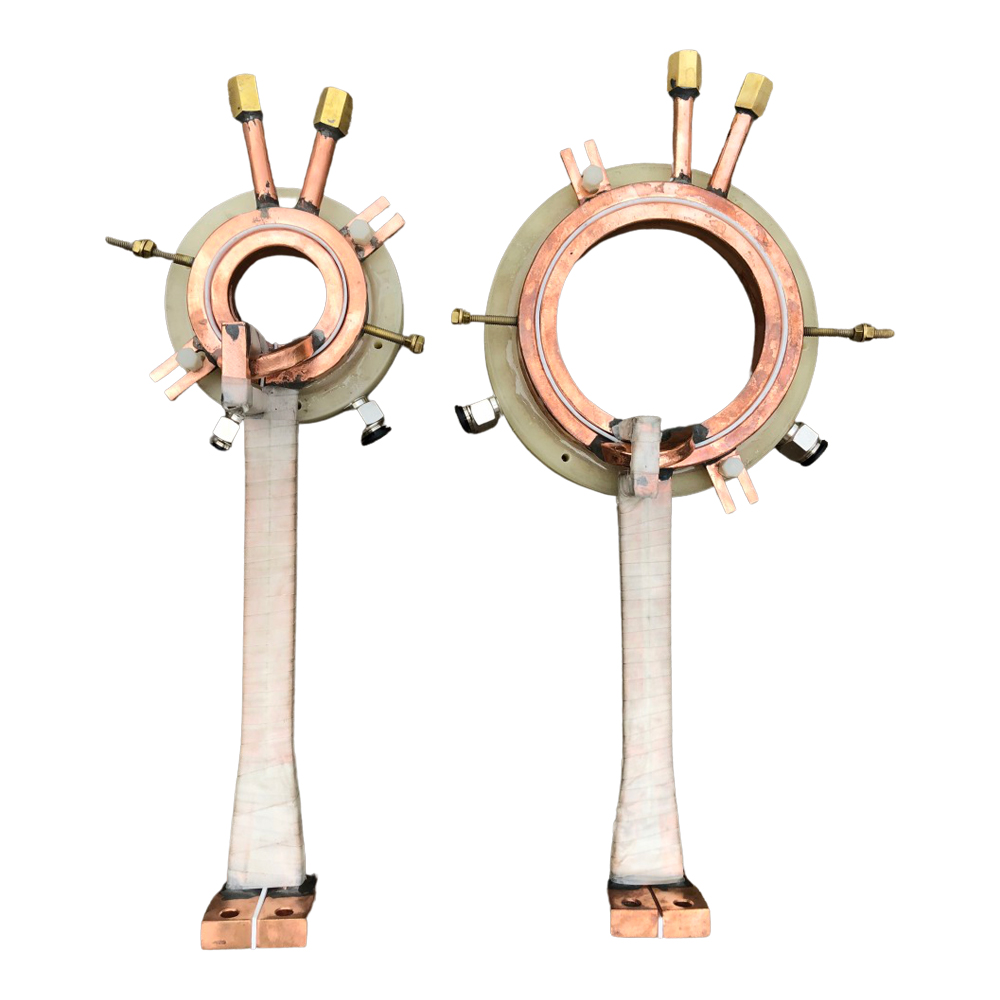

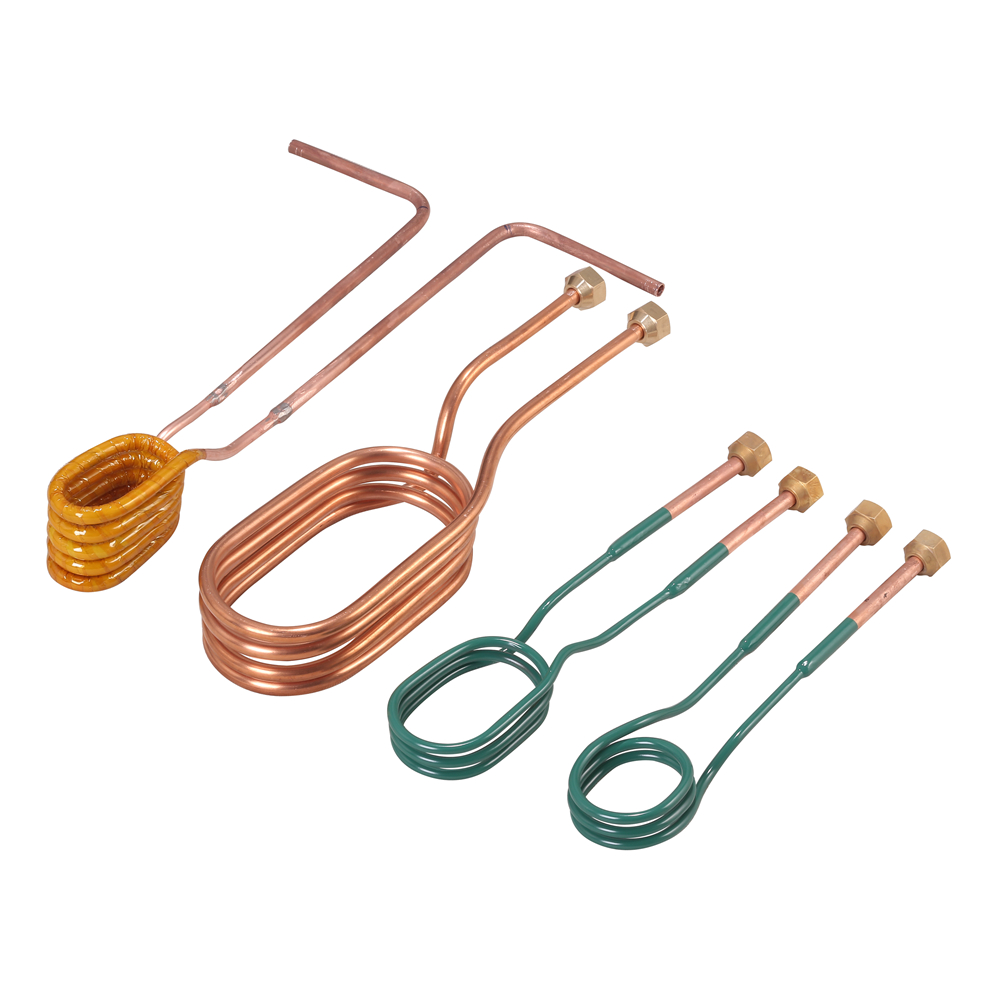

The induction coil, also known as an 'inductor', is essential to induction heating. It is the output head of the induction heater. Many factors contribute to a coil's effectiveness: the care taken to make it, the quality of the materials used, its shape, its maintenance, its correct matching with the power source, etc. That's why it's so important to insist on professionally made and maintained coils. A well designed coil provides the most desirable heat pattern as well as the best efficiency. Coils which focus heat in small zones are constructed of water cooled copper tubing. Coil attachment screw locations use stainless steel helicoil inserts for durability. A quick change coil configuration is available. At LIHUA Induction, we make every type of coil, according to different workpieces and heating requirements. Single-turn, flexible, multi-turn cylindrical, left-turn, right-turn, rod-shaped, hair-pin, parallel, ear-shaped, new, reconditioned, tiny, big, unbelievably enormous...

-

FAQ

- Any tips for designing my induction heating coil?

1. Higher flux density near the heating area means a higher current is generated in the part.

2. The greatest number of flux lines in a solenoid coil are toward the center of the coil.

3. The geometric center of the coil is a weak flux path.

4. The magnetic center of the inductor is not necessarily the geometric center.

5. Coil must be designed to prevent cancellation of the magnetic field. - Why use induction heating?

★ Improved process efficiency

★ Localized, constant and precise heating

★ Temperature control

★ Energy saving

★ Possibility of integration into production lines

★ Best quality and yield/performance

★ Pollution free, fast and secure technology

★ Improved working environment. - Are you a factory or trading company?

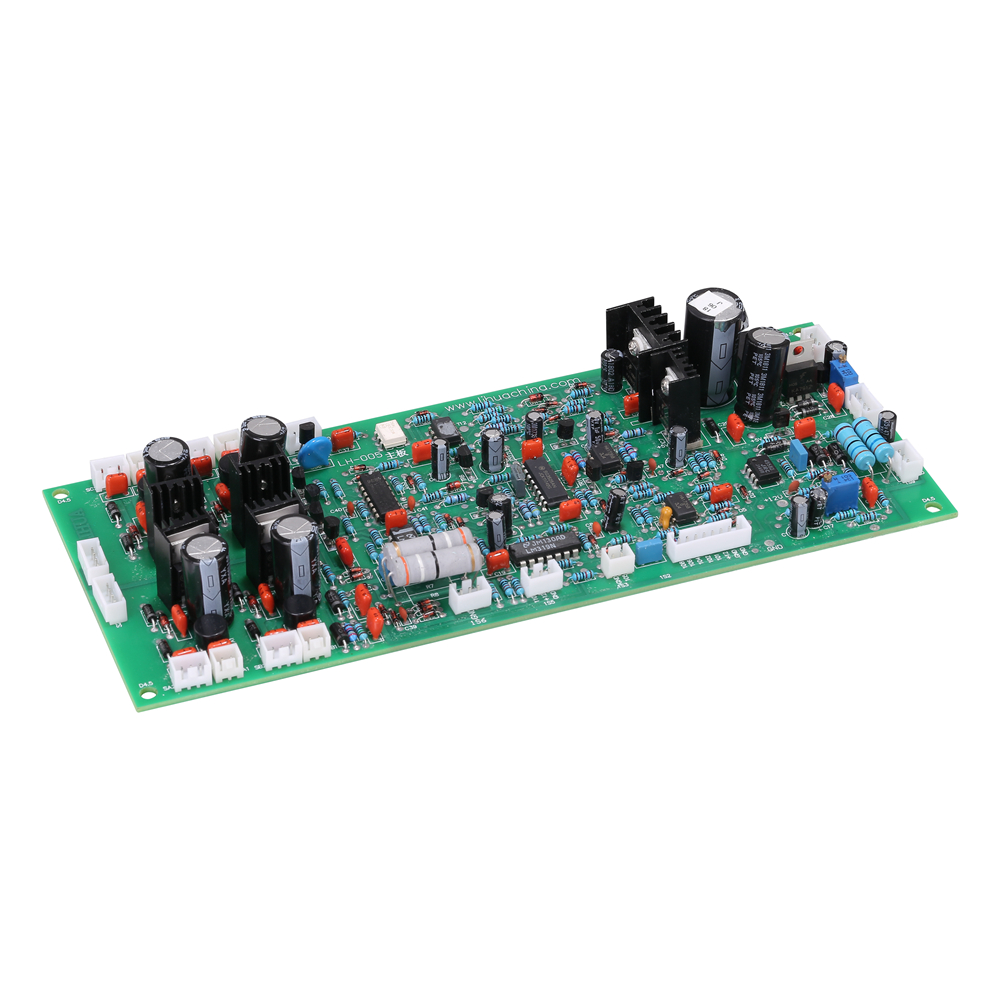

We are a professional manufacturer of induction heating equipment since 2005. Welcome to visit our factory anytime.

- Do you have any equipment in stock?

Yes, we have some standard models in stock, and can deliver immediately after payment.

- How is your quality control?

We have a professional team responsible for product testing and packaging before delivery. You can buy without hesitation.

- If the machine get damaged, what can I do?

Some spare parts are free of charge during the one-year warranty period. If you don't know how to repair, please take photos or record a video and send to us, our engineer will guide you to perform the repair. If still cannot solve the problem, we can send our engineers to your factory.

- Any tips for designing my induction heating coil?